Anaerobic digestion accelerates the decomposition processes that occurs more slowly in the oxygen

depleted environment of the waste mass within traditional MSW landfills. Anaerobic (“without-

oxygen”) bacteria metabolize organic waste to produce a biogas of methane, carbon dioxide, and

other trace gasses, as well as a soil amendment referred to as digestate, a nutrient-rich byproduct

that can be enhanced to fertilizer-grade with treatment (Pham et al., 2015).

Anaerobic digestion is fairly prevalent in the US and well understood. This process is especially

appropriate for food and agriculture (non-woody) waste, as it has high degradable potential and high

potential biogas yield (Pham et al., 2015). There are over 39 stand-alone MSW anaerobic digester

facilities in operation in the United States, and most are located in California.

Pre-treatment of influent waste degrades cellulosic components and is necessary to optimize

biogas/digestate output. Options for pre-treatment include physical pretreatment (mechanical

separation, pressurizing), thermal pretreatment (microwave irradiation, thermochemical

liquefaction), chemical pretreatment (dilute-acid hydrolysis, alkaline treatment), or biological

pretreatment (enzymatic hydrolysis) (Pham et al., 2015). Dilute Acid hydrolysis is the most common

pre-treatment (Pham et al., 2015).

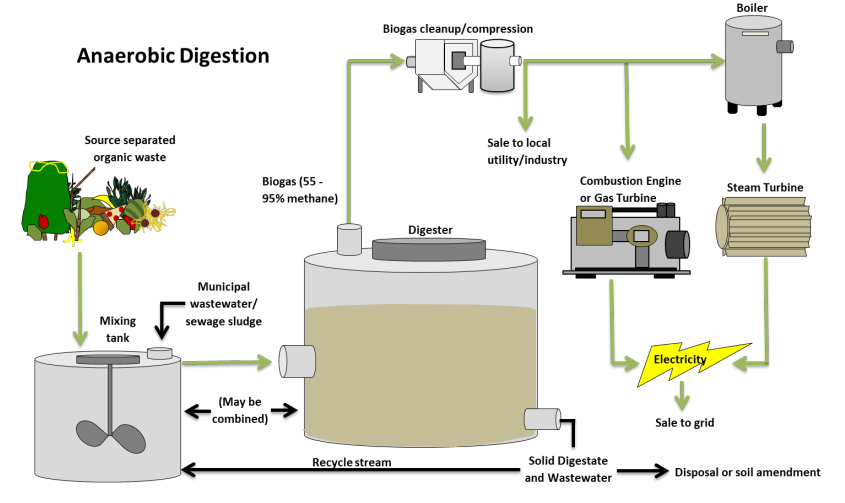

Anaerobic digestion usually uses a step-wise batch reactor process rather than a continuous

process; thus, digestible waste is combined in the same vessel and treated in discrete loads. The

waste may also be initially added to a separate batch reactor for mixing and homogenization. Exhibit

3 proposes a process flow diagram for a typical anaerobic digester system.

To maximize product output, operators must understand the multiple technical considerations of

anaerobic digestion, and they must closely manage inputs as well as process conditions within the

digester. These considerations can be complex and may exclude certain kinds of waste such as

woody yard waste and the organic fractions of construction and demolition (C&D) debris.

Solid waste can be co-digested with other substrates to produce desired byproducts, such as sludge-

derived fertilizers with specific nutrient profiles (Pham et al., 2015).