Waste-to-Energy (alternatively referred to as Energy from Waste, or EFW, more generally) is a highly-

established municipal solid waste (MSW) conversion technology. WtE can also be thought of as

“incineration with energy recovery or “mass burn” if waste is not pre-processed. WtE as a waste

disposal system generally requires MSW to be combusted at high temperatures in the range of 800

to 2200°F. WtE systems can handle virtually all non-hazardous MSW, and very little pre-processing

is required. Typically, only bulky items and chlorinated plastics are removed, although inert material

(i.e. concrete, dirt spoils etc.) as well as high moisture waste such as food or yard waste may be

avoided due to these feedstocks’ relatively low heating values. Input MSW is mixed for homogeneity.

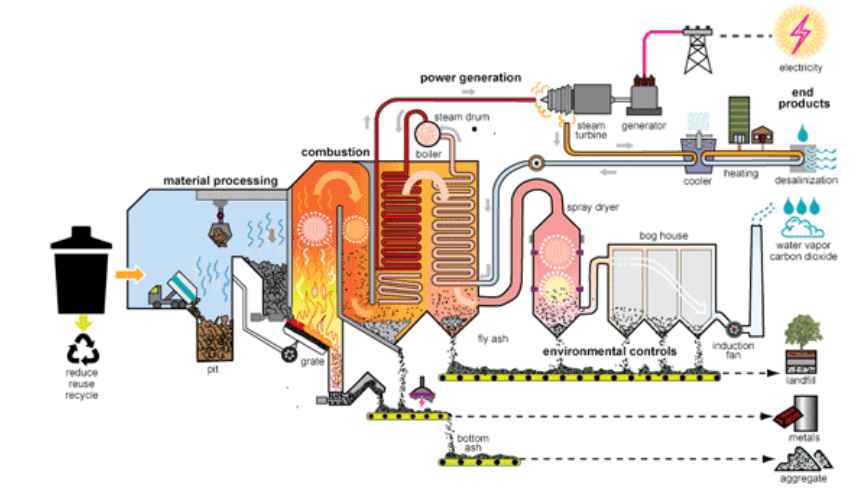

Input MSW is fed into the combustion chamber where it is incinerated, heating a boiler and

generating steam used in a turbine generator. Exhibit 1 presents a schematic of the general process.

WtE has costs and benefits consistent with many other types of waste conversion technologies.

Potential benefits of WtE systems include increased diversion of waste materials from landfills, reduced landfill development impacts, reduced (select) greenhouse gas emissions including

methane, generation of revenue streams in the form of process residuals, and provision of

complementary effects with Material Recovery Facilities (MRFs) and other recycling systems.

Potential concerns include project financing and cost, public perception and acceptance, regulatory

challenges, generation and control of emissions, and possible systemic changes required for

implementation.

Waste-to-Energy (WtE), sometimes referred to as “Energy-from-Waste” (EfW), “incineration with

energy recovery”, or “mass burn” (if waste is not pre-processed) is the best-known and most widely

adopted MSW conversion method. There are currently four WtE facilities operating in Virginia as

listed below with their estimated throughputs in tons per day and tons per year. Collectively, the

facilities process an estimated 2.1 million tons of material per year.

- Covanta Alexandria/Arlington – 975 tpd/350,000 tpy

- Covanta Fairfax – 3,000 tpd/1,100,000 tpy

- Hampton/NASA – 240 tpd/70,000 tpy

- Wheelabrator Portsmouth – 2,370 tpd/615,000 tpy

No WtE facilities are currently operational in Kentucky, North Carolina, South Carolina, or Tennessee,

although there are approximately 80 to 100 facilities located nationwide. Some WtE facilities have

historically accepted material that has been pre-processed into pelletized or “fluffed” refused

derived fuel (RDF), as it is sometimes referred to in Europe, solid recovered fuel (SRF), for

consistency of feedstock and general combustion process managability.

WtE generally occurs at combustion temperatures (800 to 2200°F) in the presence of oxygen. They

have been proven to handle almost all MSW; very little pre-process is required. Generally, only bulky

items that can impede the WtE processing line such as large furniture, metal objects, and C&D

material must be removed, although chlorinated plastics are also commonly removed for purposes

of air pollution control system efficiency. However, input MSW is mixed for homogeneity, often with

excavation equipment or overhead cranes as shown in Exhibit 5.

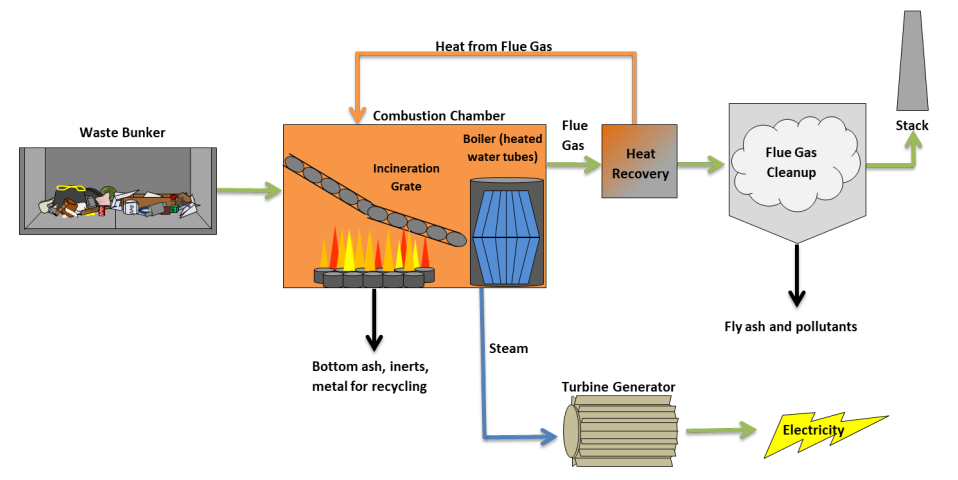

Input MSW is fed into the combustion chamber where it is incinerated, heating a boiler and

generating steam to be used in a turbine generator for electricity production. Fly ash and pollutants

are collected in a flue gas cleanup stage. Heavier ash, inerts, and metals are collected and recycled

if appropriate. Thus, as with other thermal conversion processes, a portion (roughly 10% by mass) of

material inputs to WtE system must ultimately be landfilled. Exhibit 6 presents a potential WtE

process flow diagram.

Outputs of WtE include electrical power, a relatively stable bottom ash, fly ash (must be treated with

air pollution control technologies), and extracted or otherwise recovered materials such as bulky

items and recyclable metals.

The facilities also provide cost-effective and

consistent electrical power or steam that can be sold to power producers and generate useable

process byproducts such as heat and waste metals. The revenue from these sources, in addition to

that from the tipping fees garnered from waste acceptance, are attractive financial benefits. Instead

of storing and managing waste at landfills indefinitely, incurring post-closure costs for environmental

management and maintenance infrastructure for three decades or more, waste is processed on an

as-received basis.

WtE facilities may also be a strategy for mitigating certain environmental impacts compared to other

disposal facilities such as landfills. WtE facilities must monitor and implement rigorous controls to

manage emissions of certain stack constituents, but as a whole, they can potentially reduce the

carbon dioxide and methane produced from the same tonnage of waste compared to landfills and do

not require extensive environmental monitoring following the conclusion of the facility useful life.

However, there are notable pitfalls to the implementation and operation of WtE facilities as an

integrated waste management strategy. Two of the above-discussed facilities recently experienced

major disruptions due to fires, one of which significantly damaged the facility. Fires are a risk when

any large quantity of waste is routinely stockpiled at a facility, however, and can occur at many types

of waste management facilities including transfer stations, MRFs and landfills.

As with certain landfills, WtE facilities may face community backlash, especially when located in

proximity to densely-populated areas. Both Covanta Montgomery and Wheelabrator Baltimore have

faced significant oppositional forces, in whole and in part, from entities including its host local

government, community activists and environmental groups. Proper siting considerations and the

implementation and maintenance of emission control measures can minimize any impacts.

Future community relations problems with WtE facilities can be minimized commencing with the

initiation of project pre-feasibility by fully considering all potential siting options, engaging with

community stakeholders in the conceptual planning process, educating the community about the

benefits of WtE facilities, and implementing additional environmental controls as needed.

Waste to Energy facilities can be highly beneficial to communities and owners. They are an

established method of solid waste disposal and have both benefits and drawbacks in comparison to

some other common forms of waste disposal such as landfilling. However, they come with

operational and public relations challenges that are best addressed starting in the initial stages of

the facility construction and operations.