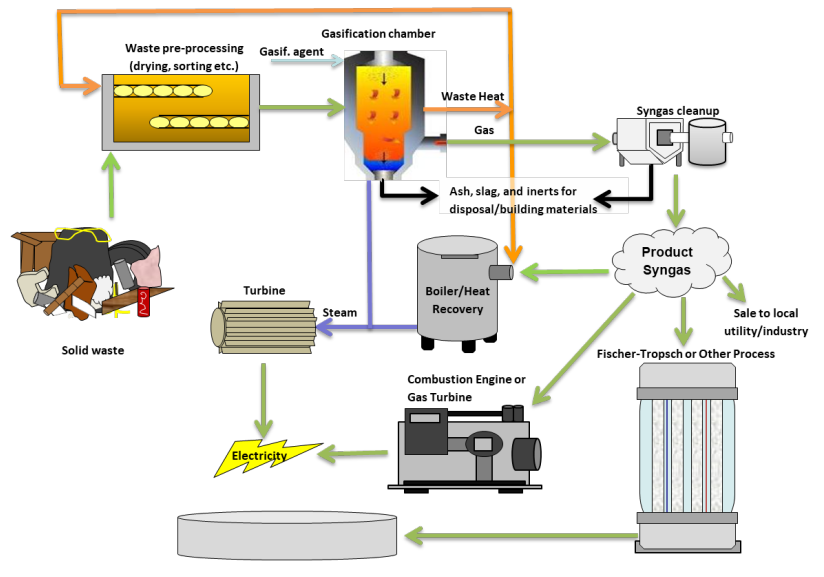

Gasification is a thermochemical transformation of carbon-based feedstock with a limited amount of

air, pure oxygen, air enriched with oxygen, or steam injected. As with pyrolysis, oxygen inputs and

resulting oxidation within the gasification system are controlled, but in gasification processes, air and

oxygen inputs are introduced in variable quantities.

Gasification requires extremely low MSW moisture content (<10%); as a result, MSW with a high

moisture content such as food waste may need to be segregated or dried prior to processing. Prior to

gasification, MSW is sorted to separate system inputs from unusable (typically recyclable) materials

such as glass, metal, inerts, and contaminants. In traditional gasification, process temperatures

range from 1,450 to 3,000°C.

Syngas and some ash/slag are produced during gasification. After production during gasification,

syngas can be cleaned, compressed, and transformed through other catalytic processes into other

industrially useful chemicals and fuels (methanol, ethanol, gasoline olefins, diesel waxes, etc.). As

with pyrolysis, varying parameters such as oxygen levels in the gasification process can result in

varying proportions of generated solid, liquid, and gas outputs